Collated nails are a staple in the construction and woodworking industries, embodying efficiency and precision in projects ranging from framing houses to crafting furniture. These small yet mighty components are more than just nails; they are a testament to the advancements in building technology that cater to speed, accuracy, and safety. In this blog post, we'll dive into what collated nails are, their benefits, the different types available, and their applications in various projects.

What Are Collated Nails?

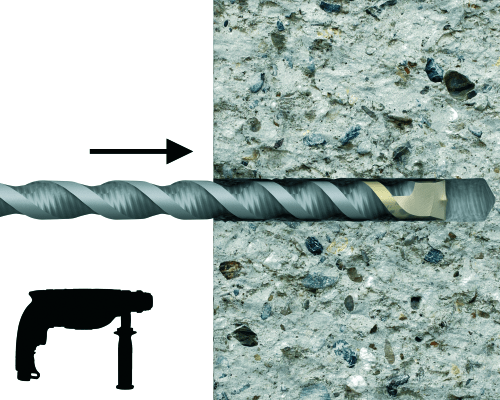

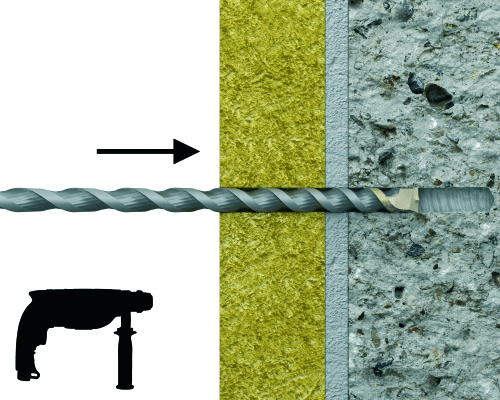

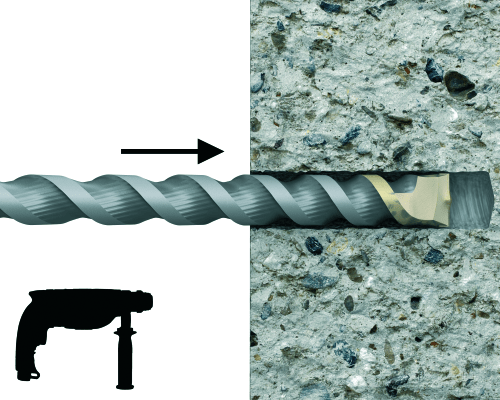

Collated nails are nails that are arranged in a strip or coil and loaded into a nail gun or nailer. They are designed to be fired sequentially into wood or other materials, making the nailing process faster and more efficient than manual hammering. The term "collated" refers to how the nails are connected together in a fixed order, which can be by plastic, wire, paper, or adhesive. This organization allows for easy and rapid firing with minimal jamming or misfires.

Benefits of Collated Nails

- Speed: Perhaps the most significant advantage, collated nails make the process of nailing quick. With a nail gun, you can drive hundreds of nails in the time it would take to manually hammer a fraction of that number.

- Accuracy: Nail guns designed for collated nails are engineered to place nails precisely. This precision is crucial for structural integrity in construction and for aesthetic purposes in finish carpentry.

- Reduced Labor: Using collated nails minimizes the physical effort required, reducing fatigue and increasing productivity.

- Safety: Although nail guns are powerful tools that require respect and caution, the risk of injury from missed hammer strikes is eliminated.

Types of Collated Nails

Collated nails come in various forms, each suited to specific tools and tasks:

- Stick Nails: Arranged in a straight line and held together by plastic, wire, or paper. These are typically used in framing and finishing nailers.

- Coil Nails: Wound into a coil and held together by wires. Coil nailers, which use these nails, have a higher capacity than stick nailers and are often used for roofing and siding.

- Different Materials and Finishes: Collated nails can be made from stainless steel, galvanised steel, or other materials, with finishes that range from bright (uncoated) to vinyl-coated, catering to different environmental conditions and project requirements.

Applications

Collated nails are used in a wide range of construction and woodworking projects:

- Framing: Constructing the structural framework for buildings.

- Roofing: Attaching shingles and roofing materials.

- Siding: Applying exterior wall coverings.

- Finishing: Detail work that requires smaller, less visible nails.

- Pallet Making: Assembling wooden pallets and crates.

Conclusion

Collated nails, when combined with the power of nail guns, revolutionise nailing tasks in construction and woodworking. Their efficiency, accuracy, and the variety available make them indispensable for professionals and DIY enthusiasts alike.

By understanding the different types of collated nails and their applications, you can choose the right nail for your project and ensure that your work not only holds together securely but also stands the test of time.

Whether you're framing a new home or crafting a delicate piece of furniture, collated nails provide the reliability and performance necessary to achieve excellent results.

See our range here:

https://www.wesupplyfixings.co.uk/collections/collated-nails